As a type of bulk materials feeder, the vibrating feeder is widely used in industries such as food, mining, coal, and building materials for the transportation of bulk raw materials due to its advantages such as high efficiency, low noise, anti - clogging, adjustable amplitude/frequency, and maintenance - free.

To improve the production efficiency of the factory using the vibrating feeder, first of all, we need to understand the structure of the vibrating feeder. After clearly sorting out our own needs, we can get a customized vibrating feeder.

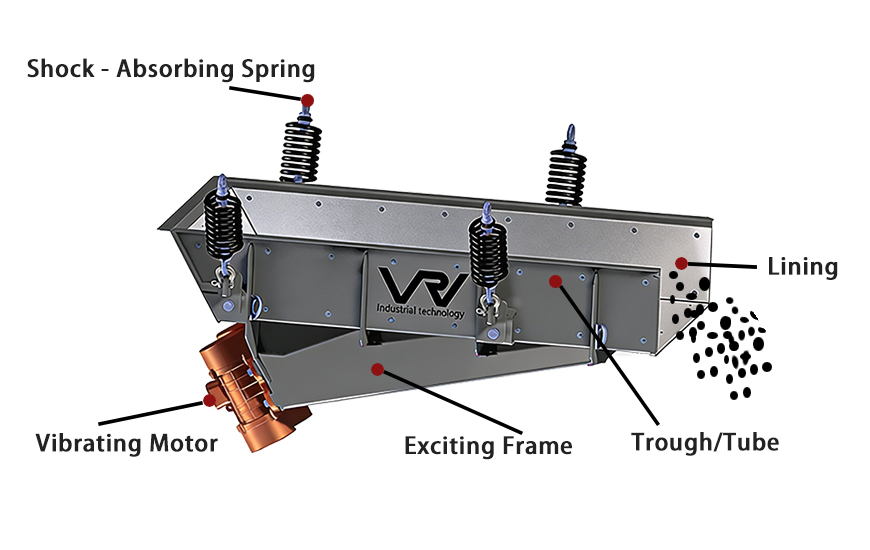

The structure of the vibrating feeder is very simple, mainly composed of a vibrating motor, a conveying trough/pipe, a vibration - exciting frame, supports, springs, liners, etc. To determine whether a vibrating feeder is of good quality, the most important thing is to look at the selection and design of the vibrating motor and the vibration - exciting frame. The vibrating feeder manufacturer needs to calculate based on parameters such as the handling capacity, bulk density, and size of the bulk materials to select a suitable vibrating motor and design the angle, length, etc. of the vibration - exciting frame.

Vibrating Motor

The vibrating motor is the

power core of the vibrating feeder. It usually adopts a double - output - shaft

eccentric block structure. By adjusting the angle between the eccentric blocks,

the magnitude of the exciting force can be changed. After being powered on, it

drives the equipment to generate directional vibration, thereby propelling the

materials to move forward along the trough. Its rotational speed and exciting

force parameters directly determine the conveying efficiency and amplitude

stability of the feeder.

Conveying Trough / Pipe

The conveying trough (or

conveying pipe) is the material - carrying and conveying channel of the

vibrating feeder. The trough body mostly has a trough - shaped or plate -

shaped structure, while pipes are suitable for the closed - conveying scenarios

of powders and small particles. Its shape, length, and inclination angle need

to be designed according to the material characteristics and conveying

requirements. During operation, it reciprocates with the vibration system, and

realizes continuous conveying by means of the throwing or sliding of the

materials. Some trough bodies are designed to be segmented for easy

installation and maintenance.

Vibration - exciting Frame

The vibration - exciting frame

is the force - transmission and connection component of the vibrating feeder.

It is generally rigidly connected to the vibrating motor and the conveying

trough. Its function is to evenly transmit the exciting force generated by the

vibrating motor to all parts of the conveying trough, ensuring that the entire

trough body vibrates synchronously and avoiding local stress concentration. At

the same time, it can also play a role in fixing the vibrating motor, ensuring

the installation stability of the motor under high - frequency vibration

conditions.

Support

The support is the support and

installation foundation of the vibrating feeder. It is mainly used to fix the

equipment on the foundation or frame. Its structural form needs to match the

overall weight and vibration characteristics of the feeder. It is usually

designed as a welded steel or cast - steel structure, having sufficient

strength and stiffness to withstand the dynamic load during the operation of

the equipment. Some supports can also adjust the height and inclination angle

to meet different installation and conveying requirements.

Spring

The spring is a key component

for vibration isolation and buffering of the vibrating feeder. It is installed

between the support and the vibration - exciting frame (or conveying trough),

and is mainly divided into types such as spiral springs and rubber springs.

During operation, the spring can not only support the self - weight of the

equipment, but also absorb vibration energy, reduce the transmission of

equipment vibration to the foundation, prevent resonance from occurring, and at

the same time, through its own elastic deformation, assist in maintaining the

stable amplitude of the vibration system.

Liner

The liner is a protective and

wear - resistant component laid on the inner wall of the conveying trough. Its

materials are mostly wear - resistant steel plates, polyurethane, rubber, and

other wear - resistant and impact - resistant materials. Its function is to

protect the conveying trough body from the direct scouring and wear of the

materials, and extend the service life of the trough body. In addition, liners

of different materials can also adjust the friction coefficient between the

materials and the trough body, optimize the conveying speed and fluidity of the

materials, and prevent the materials from adhering to the trough wall.

VRV, a professional vibrating

feeder manufacturer in China, customize vibrating feeders according to your

requirement. Contact us to get a best quotation.

ស្លាក :

ហៅមកយើង :

អ៊ីមែល : sales@vrvibratory.com បណ្តាញ ipv6 ត្រូវបានគាំទ្រ

បណ្តាញ ipv6 ត្រូវបានគាំទ្រ